The base plate for Russia’s lead-cooled Brest-OD-300 fast reactor has been successfully delivered to the construction site of the Experimental Demonstration Power Complex (ODEK) at the Siberian Chemical Combine (SCC) in Seversk, Tomsk Region. ODEK is being built as part of the Proryv (Breakthrough) project to demonstrate closed fuel cycle technology. It will include three unique facilities: a module for fabrication and refabrication (MFR) of mixed dense uranium-plutonium nitride (MNUP) fuel, a 300 MWe Brest-300 lead-cooled fast reactor, and a module for reprocessing and recycling irradiated fuel.

The base plate for Russia’s lead-cooled Brest-OD-300 fast reactor has been successfully delivered to the construction site of the Experimental Demonstration Power Complex (ODEK) at the Siberian Chemical Combine (SCC) in Seversk, Tomsk Region. ODEK is being built as part of the Proryv (Breakthrough) project to demonstrate closed fuel cycle technology. It will include three unique facilities: a module for fabrication and refabrication (MFR) of mixed dense uranium-plutonium nitride (MNUP) fuel, a 300 MWe Brest-300 lead-cooled fast reactor, and a module for reprocessing and recycling irradiated fuel.

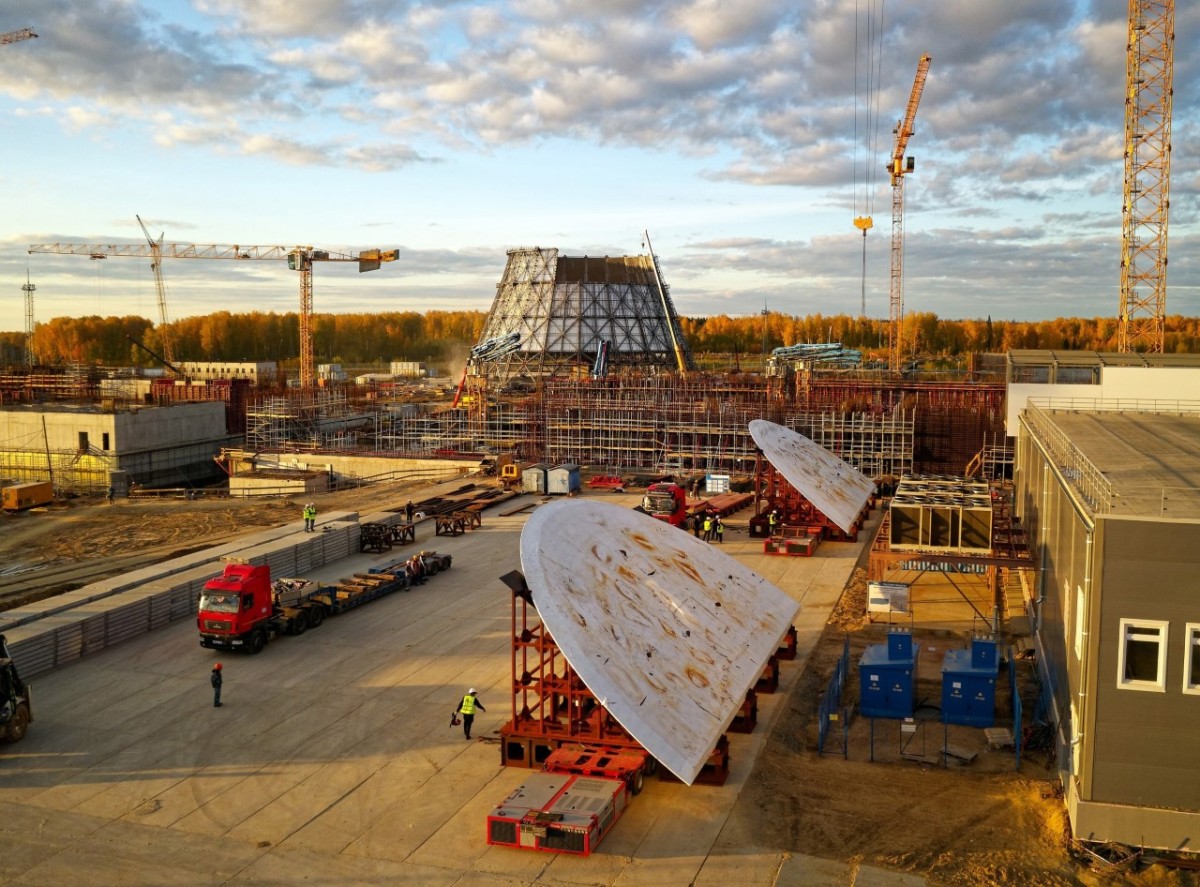

The reactor base plate consists of two halves and is a welded metal structure with a diameter of more than 21 metres and a wall thickness of 300 mm. The total weight of the slab is 176 tons. The equipment was manufactured for the first time and has no analogues in the world at any operating NPPs. The plate will be installed in the shaft of the reactor building. Its main task will be to equalise the loads on the foundation from the elements of the reactor vessel.

The slab sections were delivered to the berth of the Samus village along the Northern Sea Route with intermediate reloading from an ocean-class barge to a river-class barge in the Gulf of Ob. In the process of transportation, logistics was worked out, which will further simplify the delivery of other elements of the reactor pressure vessel.

The base plate has been placed near the building of the future reactor pending subsequent assembly of two sections into a single structure.

Traffic was restricted in Seversk to enable the delivery of large-scale equipment. SCC notified the local population that from 19-21 September, there would be delays along the Samus – Seversk highway.

Image: The two halves of the base plate for the Brest-OD-300 fast reactor at the construction site (courtesy of TVEL)