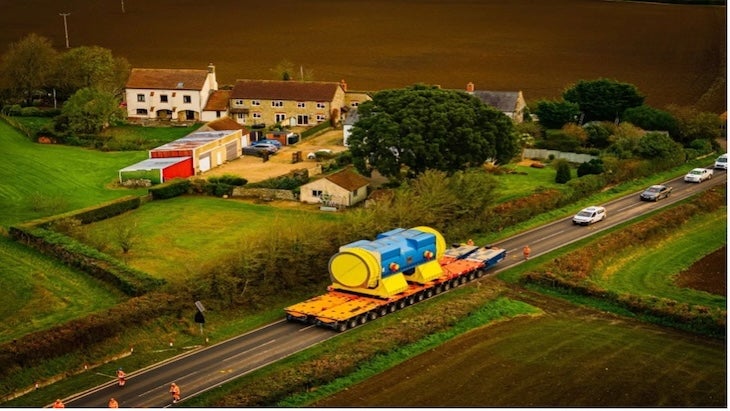

The turbine generator stator for the Hinkley Point C NPP under construction in Somerset, England, has been delivered to the site from the manufacturing plant in Belfort, France. The 450-tonne stator, measuring 12 metres in length, was supplied by EDF subsidiary Arabelle Solutions and was delivered to the construction site having been transported by road, rail and sea. The stator, a key component of the turbine generator, is the largest ever produced by Arabelle Solutions.

Hinkley Point C, comprising two 1,630 MWe EPR pressurised water reactors is being built by the Bouygues and Laing O’Rourke joint venture (Bylor JV) for client EDF Energy. Work is now expected to be completed between 2029 and 2031. Construction began in December 2018, with unit 1 originally scheduled to start up by the end of 2025. However, this was first revised to 2027 in May 2022 and in January 2024 EDF announced that the “base case” was now for unit 1 being operational in 2030. The cost has been revised from £26bn ($32.8bn) to £31-34bn in 2015 prices. The power station is expected to operate for 60-80 years.

EDF completed acquisition of a portion of GE Vernova’s nuclear conventional islands technology and services, including its Arabelle steam turbines, in May. The transaction included the manufacturing of conventional island equipment for new NPPs as well as related maintenance and upgrade activities for existing nuclear plants outside of the Americas. EDF’s acquisition of the business (formerly GE Steam Power) was first announced in early 2022 and the final agreement was signed the following November.

“It’s another big day for Britain’s energy security as the 450-tonne generator stator, which converts the mechanical energy of the turbine into electricity, arrives at the construction site in Somerset after another safe delivery by road, rail and sea,” said Hinkley Point C spokesman Gordon Bell.

Hinkley Point C says construction and operation of will create about 25,000 employment opportunities and up to 1,000 apprenticeships. An estimated 64% of the project’s construction value is expected to go to UK companies.

As well as the two reactors and associated building, the development will include:

- staff facilities, offices, workshops and storage buildings;

- cooling water tunnels and associated infrastructure, including a fish recovery and return system;

- fuel and management facilities, including for spent fuel and intermediate waste;

- a sea wall, incorporating a public footpath;

- a national-grid 400 kV substation and overhead power lines on site;

- a public information centre;

- a temporary jetty;

- an emergency access road;

- access and parking facilities for workers, visitors and deliveries; and

- a temporary accommodation campus, including 510 bed spaces.

Key contracts, suppliers and consultants include Kier BAM Joint Venture (site preparation works); Framatome SA (pressure vessel and steam generators); Bouygues and O’Rourke JV (construction contract); Sarens NV (assembling the world’s biggest crane at the site to aid construction at a later stage); MHI (pump sets); Trilium (subcontractor to MHI); Tecnatom (pre-operational inspection services); BGEN (electrical and instrumentation solutions); GE Steam Power Systems (conventional power islands); and Arabelle Solutions (stator).