Idaho National Laboratory (INL) has conducted the first safety test in more than 20 years on a high burnup fast reactor fuel at its Transient Reactor Test (TREAT) facility. The test is part of a collaboration to develop and qualify fuels for fast reactors between the US Department of Energy (DOE) and the Japan Atomic Energy Agency (JAEA). Several additional safety tests are planned over the next few years.

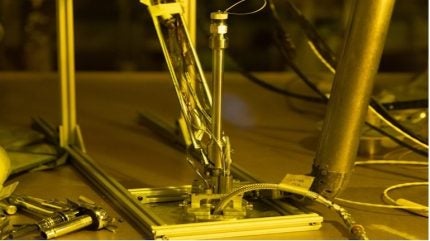

The researchers performed transient tests on a high-burnup metallic fuel that was archived from historic irradiation testing at INL’s EBR-II reactor. A new test capsule specifically designed to test fast reactor fuels was used that is equipped with a variety of sensors to monitor fuel behaviour during testing. INL said the safety tests will provide crucial new data to support future fuel development and qualification.

“The main ambition of this initiative is to test fast reactor fuels in their weakest state to better understand their limits and inform the development of improved designs,” said Colby Jensen, INL Technical Lead for Transient Testing. “Fast reactor fuel designs in the United States have not made a major leap forward since the era when the EBR-II programme was shut down, and so the data from these tests of legacy fuel is highly valuable for advanced fuel designers today.”

EBR-II was a 62.5 MWt/20 MWe demonstration liquid-sodium cooled, fast breeder reactor used to test fuels and materials. It was shut down after 30 years of operations and has since been decommissioned. However, its containment structure is being repurposed to house the National Reactor Innovation Center’s DOME test bed facility.

The DOE/JAEA safety tests are part of a five-year cost-shared facility sharing initiative under the Civil Nuclear Energy Research & Development Working Group. They are testing a mixed oxide fuel used by current Japanese fast reactor designs and a metallic alloy fuel under development in the US and of interest to Japan. DOE and JAEA previously performed similar tests on high-burnup fast reactor fuel in the late 80s before EBR-II was shutdown. TREAT, which was launched in 1959, was placed on standby in 1994.

TREAT restarted in 2017 under the Trump Administration to support the development and qualification testing of new fuels. It is one of the few test reactors in the world that can perform transient tests, which produces short duration power cycles. These may be more than ten times higher than a commercial power plant and help to determine the safety limits of nuclear fuel.

Post-irradiation examination work will be performed at INL’s Hot Fuel Examination Facility and Irradiated Materials Characterisation Laboratory, where researchers will use state-of-the-art analytical capabilities to examine the test specimens down to the microstructural level. The initial project experiments are expected to be completed later this year with planning for additional testing already underway.

INL’s capsule also brings new testing capabilities to TREAT that will help advance fuel performance research for sodium-cooled fast reactors. “Execution of these unique experiments is an important step toward developing global confidence in the enhanced performance and safety of advanced nuclear reactor technologies,” said Dr Daniel Wachs, the national technical director for the US Advanced Fuels Campaign. “It’s also a remarkable example of how critical international collaborations will enable the next generation of energy technology development.”

TREAT is one of just a handful of reactors in the world designed specifically to bring nuclear fuels to failure in a controlled environment. The test reactor produces sudden bursts of energy, known as transients, that are five times more powerful than a commercial power plant.

Although TREAT was originally constructed to test fast-reactor fuels, its flexible design has also enabled its use for testing of light-water-reactor fuels as well as other exotic special-purpose fuels, such as space reactors. TREAT has an open-core design that allows for ease of experiment instrumentation and real-time imaging of fuel motion during irradiation, which also makes TREAT an ideal platform for understanding the irradiation response of materials and fuels on a fundamental level.