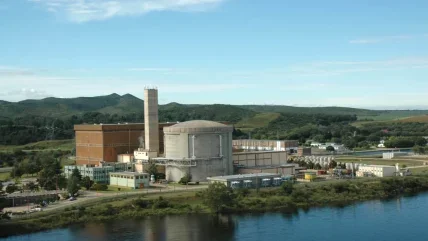

LOCATED IN THE PICTURESQUE CALAMUCHITA Valley, the town of Embalse is about a hundred kilometres south of Córdoba, the second-most populous city in Argentina. With a population of 15,000 people, Embalse is home to Argentina’s Candu 6® pressurised heavy water reactor, which provides power to nearly four million people in Córdoba and the surrounding provinces. Cobalt-60 is also produced here for cancer therapy. The single-unit reactor, with an output of 683MWe, is owned and operated by Nucleoeléctrica Argentina (NA-SA) and began commercial operation in 1983.

Candus have the same life-limiting characteristics as all nuclear plants in managing ageing and irradiated materials. However, unlike reactors with large pressure vessels (PWRs and LWRs), all the critical components of a Candu reactor core can be replaced and its clock can be reset to zero.

The Embalse life extension was completed during an outage that began on 31 December 2015 with a planned duration of 29 months (from breaker open to 100% reactor output). During the same outage, there were upgrades and additions to many of the other plant systems to bring them up to modern standards, the steam generators were replaced and modifications were made to the balance of plant to increase electricity output. With all of this complete, the plant returned to service in February 2019 for another 30 years of operation.

The retubing

The Candu 6 design has 380 horizontal fuel channels that pass through a calandria vessel containing a large inventory of low pressure heavy water (D2O) as a moderator. Inside each fuel channel is a string of natural uranium fuel bundles cooled by high pressure D2O. This is the primary heat transport system, supplied by an inlet feeder tube to the fuel channel. An outlet feeder pipe carries the heated water to one of four collection headers and then to the primary side of the four steam generators.

The refurbishment of the reactor core is known as retubing, as it requires removal and replacement of the 380 calandria tubes, 380 pressure tubes, 760 end fittings and 760 feeder tubes. Retubing drives the critical path of a Candu refurbishment. SNC-Lavalin has led, or participated in, all Candu retubings worldwide (Canada, South Korea and Argentina) and has designed and built a suite of specialised tools for the safe removal and long-term storage of irradiated reactor components.

Condition assessment

Planning for Embalse’s life extension began many years prior to the outage. Condition assessment is a critical first step to refurbishment, regardless of the type of reactor. This scoping exercise looks at the ageing of materials in cables, metals and concrete, which are assessed for their fitness for service for extended operations. This is also the time to propose technological upgrades that offer value in terms of uprate, maintainability or removing obsolescence concerns. Since the retubing of a Candu reactor occupies the critical path for more than two years, it is also an opportunity to make other upgrades that will take longer to implement than a regular maintenance outage.

Ongoing reactor inspection work and engineering analysis is valuable in determining the scope and timing for a refurbishment outage. There are several methods to collect field data using advanced non-destructive examination (NDE) techniques. Typically inspection tools are deployed in fuel channels or other components to detect flaws, wall thickness, material properties, or take a replica sample of a flaw and determine its physical characteristics (size, depth, etc.).

Beyond the NDE methods, another common practice involves the periodic harvesting of scrape samples from the inner wall of pressure tubes. These samples are analysed in a lab as a way to compare the changes in material properties over time in an operating reactor.

Lessons from past projects

Embalse was the third Candu 6 plant to go through life extension, after Wolsong 1 in South Korea and Point Lepreau in New Brunswick, Canada. The Candu 6 stations are similar in reactor configuration to each other (as sister plants). An SNC-Lavalin consortium was recently awarded a contract by Societatea Nationala Nuclearelectrica (SNN) for a condition assessment of its Candu 6 reactor in Romania in preparation for life extension. Several more retubing projects have been executed and are planned for Candu reactors at the Bruce and Darlington stations in Ontario, Canada. Retubing of Darlington 2 began during the Embalse outage, and there was opportunity for collaboration and cooperation between the two projects.

The lessons learned from previous retubing projects were formally documented and instrumental in setting the project team up for success. In addition to the translation into Spanish of all documentation, a revision update was performed to account for site-specific differences and process improvements, incorporating lessons learned.

Training of local engineers and technicians on operation and maintenance of the specialised tools started several years before the outage on reactor mock-ups. The trainers were seasoned experts who were able to bring firsthand experience of using the tools and of the process of dismantling and rebuilding a Candu reactor. The body of knowledge for this specialised work continues to grow.

Eliminating scheduled overruns has been a goal in the industry for many years. At a total of three years and five days from breaker open to criticality, the successful Embalse life extension project represents a high-water mark (along with Wolsong 1 in South Korea), demonstrating that we can execute within a predictable schedule and remain within a stated budget. The keys to success of this project include excellent communication and cooperation at all levels. From government and community support to a robust nuclear supply chain, from the availability of the required skilled labour to maintaining strong relationships with the trade unions, from the utility taking a hands-on approach to ensure critical control over the project activities, to the project set-up that included win-win contracting models, there are many factors responsible for the project’s success.

Although every project has its challenges, retubing projects have not encountered a technical issue that could not be overcome. As the body of knowledge grows, we move to high predictability with the proper application of this experience.

Fuel channels and calandria tubes

The majority of the retubing work is performed from a large work platform on either face of the reactor. The three main phases are reactor disassembly, inspection and re-assembly. The step-by-step disassembly and reassembly of the reactor is performed in ‘work series’. Each work series requires a dedicated set of tools which are installed and commissioned on the work platform. Once the work crew has executed the sequence of operations successfully on the first fuel channel (or row), it continues as a 24/7 repetition of the sequence to the last fuel channel location on the reactor face. Work series typically have planned durations between 15 and 90 days depending on the complexity of the operations. Since it is a repetitive and largely predictable sequence of operations, there are production targets that map to the expected hours per channel for each operation and usually a ramp-up over the series to get to a steady state production once a rhythm is established. The Embalse project was able to set daily production records for some series, when compared with other projects.

The removal phase of the job carries the highest dose and for this reason remotely-operated robotic tools are used. Irradiated reactor components are cut, removed and packaged into long-term waste storage containers that are kept on site. The tools can be operated locally or from a separate control room known as the Retube Operations Centre (ROC).

Once the complete calandria is open and the fuel channels and calandria tubes have been completely removed, radiation-tolerant cameras can be used to inspect the inside of the vessel — otherwise inaccessible.

The calandria at Embalse was discovered to be clean and in good condition. In other retubing projects it was necessary to deploy tools to remove debris and vacuum the lower part of the vessel.

Re-assembly with new components is similar in tooling and process to that required in constructing a new reactor. The vessel is original but with new calandria tubes and fuel channels installed. The new components are prepared and measured to exacting standards in a clean room built on site.

Feeders

The first and last major series in the retubing are removal and installation of the feeders. Feeders are long carbon steel pipes 1.5 inch to 3.5 inch in diameter.

Each fuel channel is fed by a pair of feeders from either side that bring primary coolant to and from headers above and outside the reactor vessel.

Welding carbon steel pipes seems straightforward, but meticulous attention to detail is required to control weld parameters and cleanliness of the weld joints. It is crucial to prepare all materials and the weld development programmes in advance of installation and to train workers on the tools and process. The NDE technique applied for weld examination was phased-array ultrasonic testing, as in all previous retubing projects.

The Embalse project had additional scope: an upgrade to the feeder support structures to accommodate new seismic requirements. This added extra challenges to lower feeder installation.

Remotely-operated tools

Over 100 shipping containers filled with over 1000 crates containing thousands of retubing tools were sent from Canada to Argentina and back. These complex tools and their associated spare parts required a local tooling group to become knowledgeable on operation and maintenance of the equipment, and to manage the logistics and inventory through the lifecycle of the project.

Among the most complex specialised tools were those used to remove highly irradiated reactor components such as the Zr-2.5Nb pressure tubes and zircaloy-2 calandria tubes. In the case of pressure tube and calandria tube tooling, an on-board volume reduction machine crushed the old tubes into small flat squares and dropped them into a waste container. With shielding and automation, total worker dose was lower than on previous projects.

Steam generator replacement

The Embalse refurbishment included replacing the steam generator cartridges, a first-of-a-kind for Candu 6 plants.

Flow-assisted corrosion of the original carbon steel tube supports made steam generator replacement a necessity for life extension. All other Candu 6 plants have stainless steel supports in their steam generators. This offered new challenges: it meant that at times there was no access to the equipment airlock and there were significant work stoppages on the retubing project to allow for radiography of welds overhead.

Local contributions

The proximity to Córdoba meant there was local talent. Embalse benefitted from automation experts such as PLC programmers and machine builders. They operated, maintained and troubleshot the specialised tools that were built in Canada and shipped to the site. Over 97% of the more than 4000 temporary workers on site for the refurbishment project were from Argentina.

Reactor components such as pressure tubes, calandria tubes, end fittings and closure plugs were all produced locally by Argentina’s rich industrial base. Localisation of the supply chain and use of local workers was a key driver for the national nuclear utility. In the end, strong local support was a contributing factor in the project’s success, as the logistics and delivery of parts was simplified, and the local workforce minimised the need for expertise from abroad while supporting the local economy. The project issued contracts to hundreds of Argentine companies that were directly involved and provided work for thousands of companies that were indirectly involved for a total installed cost at more than US$2 billion.

Licensing and margin assessment

The Candu reactor design is nominally capable of 30 years of operation, both from original construction and after retubing. The licensing basis is typically expressed not in years but in operational hours. The original life cycle is said to be 210,000 EFPH (effective full power hours) — 30 years at a capacity factor of 80%. With the assistance of SNC-Lavalin, NA-SA was successful in completing margin assessments and obtaining approval from its regulator to operate to 225,000 EFPH.

Other utilities that operate Candu reactors and are planning a refurbishment have also obtained approval from their regulator for operation beyond 210,000 EFPH. Some utilities are currently evaluating margins to obtain such an approval, and in some cases (depending on design), it is considered feasible to further increase the operational hours to upwards of 300,000 EFPH. The result would be that the baseline design life for a new or refurbished reactor would be more than 30 years. The 225,000 EFPH granted to Embalse enabled the operation for about 32 years in the first life cycle. During this time the plant was shut down for one net year before the refurbishment for operating strategy reasons. This flexibility is valuable to a Candu operator as it plans the timing of its refurbishment outages. Theoretically, the Candu reactor design is capable of a third 30-year life cycle or a second life extension (see ‘Looking to a third life cycle‘ below).

Conclusion

The Embalse life extension project was the most extensive refurbishment of a Candu 6 station performed to date. It included replacement, refurbishment and upgrading of numerous systems and components, including the reactor, steam generators and turbine. Starting in advance during the maintenance outages was a key factor in completing the scope. Only one modification was made in response to the Fukushima accident; other requirements were already covered by the original project scope or already existed at the plant.

Reactor fuel channel replacement was implemented under NA-SA’s direction while the SNC-Lavalin team supplied the required tooling and technical advisors. Overall the tools demonstrated good performance, the technical advisors demonstrated good expertise, and the documents and procedures provided were proven to be complete and adequate. Importantly, the total dose was lower than estimated.

A first-of-a-kind steam generator replacement was successfully implemented. Fundamental to this were direction by NA-SA staff and joint development with specialised international companies.

Embalse is now operating again and will provide safe, clean, reliable electricity for the next 30 years. Many incredible people can be proud of their contribution to the refurbishment of this plant. The success of this project is important for Argentina’s electricity needs and continues the Candu technology legacy.

Looking to a third life cycle

Theoretically, the Candu reactor design is capable of a third (30 year) life cycle (a second life extension) although it will be approximately 20 years until this is required, based on the current operating fleet. As with the first life extension, the life-limiting components that would have to be assessed are pressure tubes, calandria tubes, feeders, the calandria and the steam generators.

The calandria cannot practically be replaced if found to be a limiting factor. But in the low pressure, low temperature and low neutron flux environment in which it operates, there is at present no known obstacle to the calandria vessel remaining in service for a third life cycle. Inspections performed in the accessible areas during refurbishment support that hypothesis.

The steam generators are also theoretically expected to last 90+ years. The life-limiting component is the heat transfer area, which can be replaced in situ, as the Embalse project demonstrated. Currently, no Candu 6 steam generator is expected to be challenged over 90 years of operation. The remainder of the Candu reactor components can be replaced/repaired during regular outages.

Author information: Tim Freeman, SNC-Lavalin project director for the Embalse life extension project; Gustavo Diaz, Embalse Retubing Director NA-SA

All photos copyright Nucleoeléctrica Argentina S.A.