Fuel & fuel cycle

Reactor conversion

8 March 2010A 1970s project to reduce the amount of high-enriched uranium in circulation by converting research reactors to low-enriched uranium silicide fuel was mostly completed in the last decade. A promising new uranium-molybdenum fuel should finish the job. By Daniel Wachs

In no arena is the issue of nuclear proliferation more pressing than the international research and test reactor community where the development of cutting edge nuclear reactors for medical isotope production and as tools to support scientific study in many fields has lead to the routine use of the high enriched uranium nuclear fuels. Because these reactors are designed to provide the maximum neutron intensity possible, the fuel requires a very high loading of fissile uranium (U-235). To accomplish this, the reactor fuels are designed to maximise the uranium content. Once the fabrication limit was reached, designers began to use higher uranium enrichments where the fraction of U-235 atoms is increased from 0.7% that occurs naturally in mined uranium to as high as 93%.

By the late 1970s nearly all state-of-the-art reactors were constructed based on 93% enriched fuel. In 1978 the International Atomic Energy Agency (IAEA) identified several hundred high enriched uranium (HEU)-fuelled civilian research reactors worldwide. (HEU is defined as >20wt% U-235). It was also recognized that operation of these reactors required a large international network to support civilian commerce in this material. The existence of this network was identified as a significant nuclear proliferation risk as this material would likely be very suitable for the construction of a simple nuclear weapon.

Recognizing this risk, the US Department of Energy created the Reduced Enrichment for Research and Test Reactors (RERTR) programme in 1978. From its inception the programme was tasked with providing the means necessary to enable research and test reactors worldwide to convert from highly enriched nuclear fuel to low enriched nuclear fuel without compromising the critical services they provide to the international community. High uranium density replacement fuel development has always been a central component of the programme. In its earliest years the programme was assisted with the expansion of the uranium loading limits for the common fuels of the time in order to enable enrichment reductions (most notably UZrH but also uranium aluminide and oxide based dispersion fuels). However, these improvements were not sufficient to provide the basis for widespread LEU conversions and the programme initiated the development of new fuels. The uranium silicide (U3Si2) based dispersion fuel was thus developed and qualified in the 1980s by the programme and provided a maximum uranium density increase from 1.3gU/cm3 to 4.8gU/cm3.

As a result of these accomplishments, only a handful of civilian research and test reactors worldwide are considered unable to convert due to the availability of LEU fuel. However, this relatively small group of HEU-fuelled reactors are still by the far the greatest civilian consumers of HEU worldwide. In the early 1990s the RERTR programme embarked on the development of a replacement fuel for these most challenging reactors. In 2004 the program was refocused and accelerated when the terrorist attacks of September 11 added additional urgency and the programme was absorbed into the NNSA’s Global Threat Reduction Initiative (GTRI). Aggressive timelines for completion of the fuel development programme were put in place and the Idaho National Laboratory (INL)?was tasked with leading a multi-laboratory team in the execution of a multi-national mission. Energy Secretary Abraham announced in a speech at the IAEA in Vienna on 26 May 2004 the intention to convert all US civilian reactors that use highly enriched uranium (HEU) to low-enriched uranium (LEU) by 2014. This is a driving tenet of the GTRI programme.

Identifying Candidate fuels

From a nuclear performance standpoint, a comparable amount of fissile material (U-235) is required to maintain reactor power for both the HEU and LEU designs. Since the LEU fuel is 20% enriched, one in every five uranium atoms is U-235; the remaining four atoms are (nominally) non-fissile U-238. The LEU design therefore requires a fuel material with uranium density at least 5 times higher than the current HEU compounds. There are a number of materials that meet this standard (including both intermetallic uranium compounds and uranium metal alloys). The trick is finding one capable of withstanding the structural damage caused by the fission events occurring inside the material. When an atom fissions it splits into two pieces that collide with the atoms nearby, damaging the atomic structure, and ultimately taking up space inside that structure. The combination of these two actions (damage and new atoms) lead to expansion of the fuel material (known as swelling). Some materials accommodate these effects very well and others do not. The challenge is to find a high uranium density material that is very stable under these conditions.

A series of irradiation tests were conducted in the INL’s Advanced Test Reactor (ATR) to investigate the irradiation performance of several candidate fuel materials. These tests showed that uranium-molybdenum alloys (U-Mo) with between 6 and 12 wt% molybdenum were the ideal base for further fuel development activities. This fuel offered very high uranium density and demonstrated excellent irradiation behaviour under a wide range of relevant conditions. In particular, it exhibits very stable swelling under irradiation at temperatures up to at least 300°C.

The HEU replacement fuel was originally envisioned as a dispersion-type fuel capable of almost twice the uranium density (8-9gU/cm3) of any other research reactor fuel available. Dispersion fuel designs allow the fuel material to be broken up into very small pieces that are ‘dispersed’ into a matrix material. The irradiation damage can therefore be focused into the fuel material which is encapsulated by the matrix material. The matrix material is not subjected to the damage caused by fission events and is therefore very stable under irradiation. Dispersion fuel designs are well know to be the most robust fuel designs possible, which is why they were originally selected for research reactors applications.

An alternate ‘monolithic’ version (Figure 3) was later proposed to enable uranium loading up to four times the current state of the art (15-16gU/cm3). This is accomplished by replacing the heterogeneous U-Mo/aluminium core with a solid U-Mo foil core. In the monolithic fuel design, the two phase mixture of fuel and matrix in a dispersion fuel is replaced by a solid piece of fuel (in a foil form). However, because the fissile material (U-235) is mixed with so much non-fissile material (U-238) it acts almost like a dispersion fuel in that the fissile uranium is encapsulated by the non-fissile uranium.

Although the U-Mo is being evaluated for additional reactors, the project is currently developing the fuel to the point where it may be applicable for up to 20 reactors. Conversion studies to evaluate ‘feasibility’ have been completed for all the western reactors and are being considered for the Soviet-designed reactors.

Fuel development

The development of a new nuclear fuel requires that the developer address a wide range of issues including the development of fuel fabrication technology, irradiation testing, characterization of irradiation performance, fuel performance modelling, measurement of critical fuel material thermal and mechanical properties, and identification of a final disposal route for the fuel. While the dispersion version of the U-Mo based fuel does not come without challenges it is a relatively modest change compared to the monolithic version, which represents a dramatic shift from conventional fuel designs and challenges the status quo at many levels.

Any new fuel requires the development of fabrication processes. In some cases its very simple, in other very complex and the RERTR fuel development programme has a mixture of both.

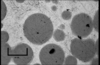

For the dispersion fuel this requires technology to make small fuel particles. These particles are then mixed with aluminium particles (that make up the matrix material) and compacted into a pellet. The pellet is inserted into a aluminium frame (which will eventually become the cladding) and hot rolled out into a thin plate. This hot rolling consolidates all the particles and bonds the fuel meat to the cladding. For the U-Mo system, the only departure from current technology is the technique used to fabricate the fuel particles. Several processes have been successfully demonstrated at this point.

It is a much different situation for the monolithic fuel. Processes have been developed for alloying and casting the fuel into ingots, rolling those ingots into thin foils with an even thinner zirconium layer attached, and bonding the aluminium cladding to the finished foil. A significant amount of R&D has been required to accomplish this task.

Testing

Irradiation Testing: The only way to evaluate how a material will perform in the reactor is to expose it to representative irradiation conditions. Irradiation tests have been conducted in the INL?ATR on over 300 fuel samples to date (with another 100-200 planned). This reactor is specially designed to conduct material and fuel irradiation tests and currently supports a number of R&D programmes. These tests start with small, low power samples and progress all the way to prototypic reactor fuel assemblies.

Characterization of Irradiation Performance: Evaluating the performance of each experiment requires detailed examination of the samples after irradiation. Because the samples are very radioactive after irradiation (due to decay of fission products), they must be handled remotely behind significant lead and/or concrete shielding (i.e. in ‘hot cells’). Each plate is examined non-destructively (visual, dimensional, etc.) and destructively (sectioned and examined under microscopes) to determine how the plate has responded to irradiation. A combination of ‘engineering scale’ and ‘scientific scale’ data is extracted from these examinations. The engineering scale data helps determine how well the fuel design would meet in-service requirements and the scientific scale data helps us determine how to improve or explain that behaviour.

Performance Modelling: Because performance can’t be measured or evaluated under every condition, it is important to develop fuel performance models that allow the developer to interpolate between measured conditions.

Disposal: While the US currently does not intend to reprocess spent nuclear fuel, our international partners are required to do so. As a result, any fuel developed to support conversion of international reactors must have a demonstrated recycle path prior to implementation. Studies are therefore conducted by the fuel development programme to demonstrate that the fuel is compatible with current recycle technology.

While research and test reactors typically operate at low temperature (coolant temperature below 100°C), the operating conditions are among the most severe in the nuclear industry. The fuel must be able to tolerate extremely high power density and burnup conditions. While a typical pressurized water reactor fuel element operates at a peak fuel power density on the order of 5KW/cc, research reactors operate as high as 17KW/cc in the fuel meat. In a power reactor, burnup is limited to well less the 10% of the heavy metal while many research reactors will see complete depletion of heavy metal in peak locations. Achieving and demonstrating satisfactory performance under these conditions is extremely difficult. Defects of concern typically lead to localized corrosion, ‘blistering’ of the fuel plate, or cracking of the cladding. In the end these defects can lead to small pinhole leaks in the fuel plate. The current fuels are so mature that leaks have become rather rare. A certain number of leaks are tolerable but they impact the cost of operating the reactors and a lot of effort is spent to minimize them.

Over 300 test specimens have been subjected to irradiation testing during the last 10 years in order to establish a fuel design worthy of pursuing generic ‘qualification’ from the US Nuclear Regulatory Commission (NRC). A wide range of fuel performance issues were identified and corrected over the course of this testing, most significantly the elimination of materials formed at the interface between aluminium and U-Mo that exhibited instability during irradiation. In the case of the dispersion fuel design, large blisters were observed to form on the fuel plates at high burnup due to the localized accumulation of fission gases and subsequent mechanical deformation of the fuel plate.

It was discovered during examination of these blisters that the U-Mo-Al interaction product was not capable of accommodating fission gases. These gases would rapidly coalesce into large bubbles observed on the surface of the plates. This behaviour was corrected by the addition of a very small amount of silicon to the aluminium matrix. The presence of silicon in this region drastically modified the interaction rate between the fuel and aluminium as well as the irradiation behaviour of the material that did form. Although the molecular silicon effects are not yet clear, adding silicon to the U-Mo-Al interaction product changes the chemistry of the material and the strengthens the bonds that tie the atoms together such that they resist the agglomeration of fission gases better.

Similar observation were made in the monolithic fuel design where delaminations could form along the interface between the fuel foil and cladding due to the presence of this unstable U-Mo-Al interaction product. This phenomena was eliminated by the addition of a thin layer of zirconium between the fuel and cladding.

The U-Mo-Al interaction phase only forms when you have contact between the U-Mo fuel and the Al cladding. We eliminated this interface by putting the Zr layer between them.

Certification

Having identified an acceptable design, the programme is aggressively working toward achieving generic ‘qualification’ of the U-Mo based fuels for use in reactors around the world. This process requires technical examination of many fuel performance features but will be crowned by the irradiation testing of fuel plates and elements in the most representative conditions possible. This is being accomplished through fabrication of U-Mo based elements for testing the in INL ATR and the international partner programmes. In parallel with this demonstration effort the programme is working to amass a complete database describing the thermal, chemical, and mechanical properties of the U-Mo fuel system both in the as-fabricated conditions and in the irradiated condition.

The programme started testing in the mid-1990s (fuel development programmes typically take ~20 years). At this point individual plates of prototypic size have been tested and plans are in place to test a set of plates in a partial element configuration this year. A prototypic fuel element (using the ATR element configuration) is planned for 2010. If successful a performance summary report will be submitted to the NRC. If the fuel is approved by the NRC it will allow reactors to initiate formal conversion requests (also to be approved by the NRC).

It is clear the development of a new nuclear fuel is a time consuming and expensive proposition. However, it is also a tremendous opportunity to expand the number of tools available to the nuclear system designers. With emergence of many new reactor concepts over the last few years that are focused on compact, lifetime cores, the driving need for a robust, high density, high burnup fuel will likely extend beyond the realm of research and test reactors. The novel technologies being developed to fabricate this fuel also open the opportunity to economically and reliably manufacture very complex fuel systems that could further optimize the operation and safety of advanced nuclear systems.

Author Info:

Daniel Wachs, GTRI Technical Lead for Fuel Development, Nuclear Fuels Performance Department, Idaho National Laboratory, PO Box 1625, Idaho Falls, ID 83415-3860.

Related ArticlesIAEA focuses on fuelling of research reactors Molybdenum-99 market supply and demand DoE nuclear site security lacking NNSA converts two US research reactors from HEU to LEU