US BWX Technologies (BWXT) Advanced Technologies subsidiary has signed a cooperation agreement with the State of Wyoming to evaluate the requirements for siting a fuel fabrication facility in the state. BWXT is evaluating locations for a potential new TRISO (TRI-structural ISOtropic) nuclear fuel production facility to support anticipated future demand for advanced reactor deployment.

The 18-month effort will evaluate potential factory locations, product specifications, facility design and engineering, estimated capital expenditures and operating costs, staffing and worker skill requirements, supply chain necessities, licensing and other requirements. This will help to establish the baseline for facilities necessary to meet anticipated demand for TRISO fuel and will include establishing the scale necessary for economic viability.

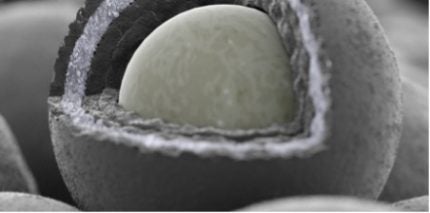

TRISO fuel comprises three layers of carbon and ceramic materials that surround kernels or balls of high-assay low-enriched uranium (high-assay low-enriched uranium (Haleu) fuel. The coatings have uniform characteristics in all directions. Fuel particles, each the size of a poppy seed, are enriched to a level four times higher than fuel used in most of today’s commercial nuclear reactors. The coatings retain fission products, making each particle its own containment system. They also protect the fuel from the factors that most degrade performance in conventional reactors – neutron irradiation, corrosion, oxidation and high temperatures.

The US Department of Energy (DOE) describes TRISO fuel as “the most robust nuclear fuel on Earth” given its ability to withstand high temperatures, resist corrosion and act as its own containment system. TRISO is an ideal fuel source for advanced reactor designs requiring different fuel configurations and enrichments than are common to conventional large reactors connected to the grid today.

“For approximately 40 years, BWXT has furnished nuclear fuel across numerous government and commercial markets, giving the company a unique and highly credible background from which to draw on as we review options for a potential new facility,” said Joe Miller, President of BWXT Advanced Technologies.

Wyoming Governor Mark Gordon said the possibility of a nuclear fuel fabrication facility was exciting. “As the world’s energy demands continue to rise, Wyoming must stay focused on protecting our core industries while continually augmenting our sources of energy. Wyoming has it all. Nuclear has been a stalwart in our energy portfolio, and like coal, can start with raw materials mined in Wyoming, processed in Wyoming, and used in Wyoming. A true trifecta.”

BWXT has been involved with the State of Wyoming since 2023 in evaluating options for constructing and deploying nuclear microreactors in the state. BWXT is currently working on a contract with the Wyoming Energy Authority to assess the viability of deploying small-scale nuclear reactors in the state. It has also signed agreements with Wyoming-based businesses such as L&H Industrial, Tata Chemicals Soda Ash Partners LLC and others in support of the goal of microreactor deployment.

BWXT says its Specialty Fuel Facility in Lynchburg, Virginia, “perfects the fuel fabrication techniques required to support the corporate objective of developing passively safe, compact nuclear reactors capable of economically generating electricity and hydrogen”.

As a participant in the DOE Office of Nuclear Energy’s Next Generation Nuclear Plant (NGNP) programme for more than 15 years, BWXT has developed the expertise to manufacture TRISO fuel. Under DOE’s Advanced Gas Reactor (AGR) Fuel Development Programme, BWXT has manufactured and certified TRISO-coated kernels and fuel compacts in production-scale quantities.

BWXT notes that its existing TRISO fuel production line, “along with our ongoing increases in capacity, allow us to meet emergent client interests in Department of Defense microreactors, space reactors, and civil advanced reactors”. By co-locating the TRISO production line with other existing uranium processing capabilities, BWXT has built a vertically-integrated facility capable of handling all TRISO-related needs, from feedstock preparation through to uranium recovery and purification.