Tokyo Electric Power Company (Tepco) is preparing to dismantle tanks containing treated water at the Fukushima Daiichi NPP site in order to make space to store nuclear fuel debris removed from the unit 2&3 damaged reactors.

Contaminated water, used to cool the melted reactor cores in the aftermath of the 2011 nuclear disaster at Fukushima, is stored in around 1,000 huge tanks at the plant containing more than 1.3m tonnes and total storage capacity has been reached. The contaminated cooling water and groundwater is treated by the Advanced Liquid Processing System (ALPS), which removes most of the radioactive contamination, with the exception of tritium, after which it is stored in another set of welded tanks.

The treated water is then diluted with seawater to one-fortieth of the concentration permitted under Japanese safety standards before being released through an undergound tunnel one kilometre offshore. About 1.3m tonnes of water has so far been treated.

Tepco said it is currently dismantling the flanged tanks in E area in order to make space to construct facilities for retrieving fuel debris from unit 2, and also plans to build facilities to retrieve fuel debris from unit 3 in the J8/J9 areas near E area. Tepco provided a map showing the positioning of the tanks.

The dismantling will start with the J9 area tanks which will be emptied first in conjunction with the discharge of ALPS treated water into the sea. The J9 area tanks dismantling period is scheduled from 13 February to the end of FY2025.

Dose measurements were taken in the J9 area between 28 November 2024 and 28 January 2025. Results confirmed that radiation levels inside all of the J9 area tanks are equal to background levels and are low enough to go forward with dismantling, “but we will continue monitoring during tank dismantling and install dust samplers on bucket trucks, tripod poles, and the existing railings on the top of tanks”.

If an abnormality is discovered in dust measurements, work will be suspended and countermeasures, such as the spraying of water and enhanced dust collection, etc., will be implemented. Work will restart only after it has been confirmed that conditions have returned to normal.

Preparations, such as treating the residual water in the J9 area tanks and removing obstructions in the vicinity began in July 2024, and since 4 February Tepco has been removing the connecting pipes between the tanks as part of preparations.

The J8 area tanks are being used to store treated water to be re-purified and this water needs to be transferred to another tank group that has been emptied. Dismantling will begin after this water has been transferred. The J8 area tank dismantling period will be reviewed depending on the schedule for transferring residual water out of the tanks. Tepco notes: “Also, since these will be the first welded tanks to be dismantled, we shall accumulate knowledge, confirm procedures and prioritise safety as we move ahead with dismantling while refraining from conforming to the schedule for schedule’s sake.”

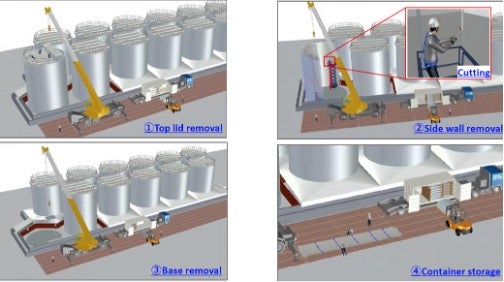

The tanks will be dismantled in the order of top lid, side walls and then base. The top lid (including ladders) will be dismantled by removing the bolts and cutting it with gas cutting machines, etc. The sidewalls and base will be cut with gas cutting machines and the fragments moved with a crane. The tanks will be dismantled in pairs.

The dismantled fragments (top lid, sidewalls, base, ladders, etc.) will be cut into sizes that can fit inside a shipping container and stored in 20-foot full height containers. The containers containing tank fragments will be moved to the primary storage area. Tepco plans to use about 3.5 20-foot full height containers for each tank. As there are 12 tanks in total in the J9 area, approximately 42 containers will be used.