Iowa University, in collaboration with the Department of Energy (DOE), has begun work on the DREAM TEAM project to investigate the use of 3D printing technology to manufacture heat-resistant tungsten shields for nuclear reactors.

“This work in advanced manufacturing, particularly in using additive manufacturing, is about making a difference,” said Sougata Roy, an Iowa State University assistant professor of mechanical engineering and a Building a World of Difference Faculty Fellow in Engineering.

Roy has a four-year, $1m grant from DOE to study the possibilities of using additive manufacturing, known as 3D printing, to create shields and components that could be used in nuclear reactors.

The grant will allow Roy, as the lead researcher, to assemble what he calls a DREAM-TEAM project – Developing a Robust Ecosystem for Additive Manufacturing of Tungsten for Extreme Applications and Management. “One of the major things that excites me about this project is working with nuclear energy,” Roy said. “It’s the largest source of clean power in the United States. This emission-free electricity is important for the future.”

Joining Roy on the project are Yachao Wang, an assistant professor of mechanical engineering at the University of North Dakota, and researchers from three DOE labs – Ames National Laboratory on the Iowa State campus, Argonne National Laboratory in Illinois and Oak Ridge National Laboratory in Tennessee.

The grant is part of a $36m effort by DOE’s Established Program to Stimulate Competitive Research (EPSCoR). The programme is designed to build energy-related research capabilities and expertise across the US.

The researchers will work with tungsten – a material being considered for the inner walls of fusion reactors because it maintains strength at high temperatures, has a high melting temperature, resists erosion under high-energy neutron irradiation and retains low levels of radioactive tritium.

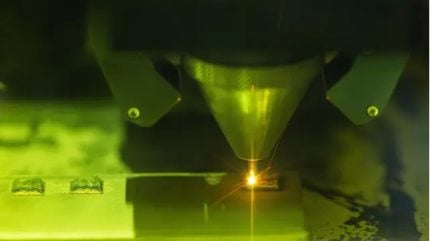

However, tungsten is hard and brittle and expensive for conventional manufacturers. The researchers will, therefore, try 3D printing tungsten-based alloys using technology known as laser powder-blown directed-energy deposition. This involves using a laser under oxygen-controlled conditions to process tungsten powder and, layer by layer, print the metal.

Roy, who has experience in 3D printing other steel-based alloys for nuclear energy applications, said the project will allow him to purchase a new instrument to characterise the mechanical properties (including the instrumented indentation characteristics and the fracture toughness) of the printed samples. According to Roy, the most unique part of the project is the physics-based modelling and computational simulations of the printing process that will complement the experimental work.

The modelling and simulations, which will include work with machine learning and artificial intelligence tools, will help researchers establish the theories behind their experimental results. The simulations will also help them develop recipes for tungsten alloys that can withstand the extreme conditions inside a nuclear reactor. “We’ll start with pure tungsten,” said Roy. “Eventually we’ll develop new alloys to resolve this cracking challenge.”