France’s Framatome has completed a two-year test programme for the industry’s first spray-in-place liner system for buried piping rehabilitation. Framatome said the results validate the structural liner system for use in NPP safety-related applications for long-term plant operations and licence renewals.

France’s Framatome has completed a two-year test programme for the industry’s first spray-in-place liner system for buried piping rehabilitation. Framatome said the results validate the structural liner system for use in NPP safety-related applications for long-term plant operations and licence renewals.

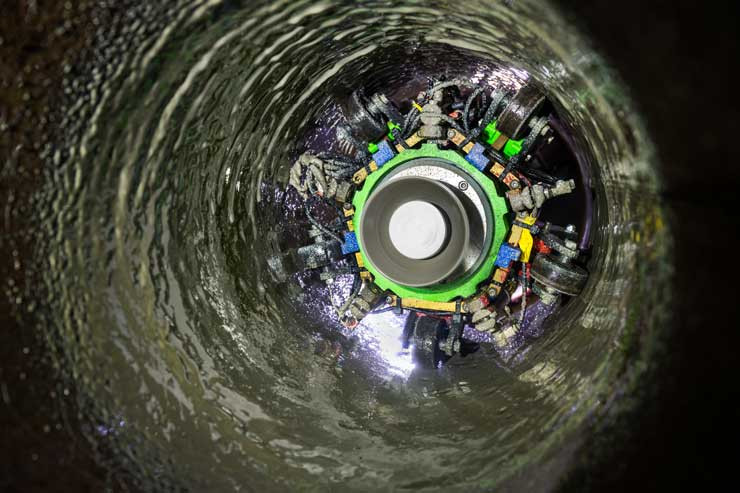

Framatome, working with industry partners, has developed an engineered structural spray-in-place liner system that is delivered remotely via in-pipe robotics. Using a robotic crawler, the fast-curing liner is sprayed evenly onto the inside of the pipe, fully rehabilitating the pipe, becoming the new pipe pressure boundary. The quick-installing system does not require excavation, thus minimizing safety risks and reducing outage duration.

Buried pipes and underground components for NPP operations range from just a few inches to 11 feet in diameter. Ageing and degradation of buried piping is an industry challenge as the location of these components make necessary repairs and inspections costly. Framatome’s spray-in-place liner provides the nuclear industry with a safe solution that rehabilitates pipe internals and overcomes cost, safety and outage duration challenges.

Craig Ranson, Senior Vice President of the Installed Base business unit in North America said “Our turnkey lining process saves our customers money and downtime, while solving buried piping ageing challenges and taking them to the end of the plant’s lifespan.” Testing and engineering evaluations were performed at Framatome’s Qualification & Testing Centre in Virginia.

Image: Framatome’s spray liner rehabilitates buried piping and underground components (courtesy of Framatome)