Idaho National Laboratory (INL) recently revealed a new molten salt test loop to support the development of advanced reactors using molten salts. It will also be used to help support the Molten Chloride Reactor Experiment (MCRE) – the world’s first fast-spectrum, salt-fuelled reactor experiment scheduled to begin at INL in the 2030s

Molten salt reactors use molten salt as a coolant, and in some cases also as a liquid fuel. They offer enhanced safety features and operate at high temperatures to generate electricity, as well as process heat which can be used by industry. A key challenge in molten salt reactor research is finding materials, sensors and instrumentation that can withstand the hot and corrosive environment within the reactor created by molten salt.

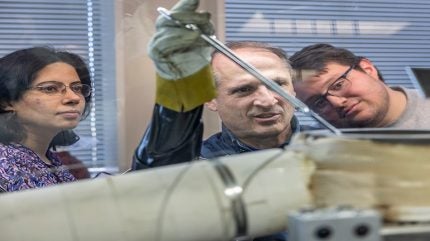

To better understand how sensors and instrumentation might perform in this type of reactor, INL researchers developed a new way to test materials by creating a molten salt test loop that more closely mimics a molten salt reactor. In addition to creating a flowing environment, where salt moves through heating and cooling conditions, the test loop can also drain and store salt in a tank when inactive, increasing the test bed’s usage and longevity.

“The instrumentation and sensor testing in flow loop environment is one-of-a-kind,” said Ruchi Gakhar, a lead scientist for INL’s Advanced Technology of Molten Salts programme. “By understanding how sensors react to high temperature flowing molten salt, we hope to advance the readiness of future molten salt reactors.” Research for the molten salt test loop was supported by INL’s Laboratory Directed Research & Development programme.

The new molten salt flow loop will inform the development of molten salt reactors, such as the MCRE, by helping to identify corrosion-resistant materials, sensors, and instrumentation capable of persisting in high-temperature environments. MCRE is one of several advanced reactor designs being supported by the Department of Energy’s Advanced Reactor Demonstration Program (ARDP).