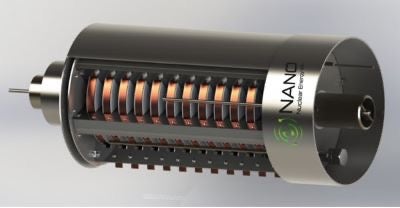

US-based NANO Nuclear Energy has acquired novel nuclear cooling technology from physicist, research engineer and project manager Dr Carlos O Maidana of Maidana Research. NANO Nuclear, is a developer of advanced microreactors has acquired novel annular linear induction pump (ALIP) intellectual property used in small nuclear reactor cooling and heat transfer.

Dr Maidana has agreed to collaborate with NANO Nuclear as a consultant on further development of the ALIP technology with a view towards achieving SBIR Phase III Award status. The Small Business Innovation Research (SBIR) programme is a federal initiative designed to support small businesses in conducting research and development with strong potential for commercialisation.

These efforts will build on previous Department of Energy (DOE) grants for the technology, aggregating over $1.37m in previous SBIR phases. These grants covered: Development of a Small Electromagnetic Pump for Molten Salt; Software for Multiphysics Analysis & Design of Annular Linear Induction Pumps; and Computational Tools for the Design of Liquid Metal Thermomagnetic Systems. NANO Nuclear will provide funding (estimated at approximately $350,000) and other resources necessary for the SBIR Phase III project with Dr Maidana as the Principal Investigator.

The SBIR programme aims to stimulate technological innovation and facilitate the transition of research into viable products and services. SBIR Phase I focuses on feasibility and technical merit, Phase II on further development and prototype creation, and Phase III on commercialisation, requiring external funding to bring the innovation to market.

The ALIP technology, based on electromagnetic (rather than mechanical) pumps, is a key-enabling technology to NANO Nuclear’s ODIN portable micro nuclear reactor design. Following the completion of Idaho National Laboratory’s (INL) review of the ODIN microreactor design in February, NANO Nuclear engineers have worked to identify relevant technologies to further optimise and simplify the design. NANO Nuclear says the ALIP technology, to be refined during the SBIR Phase III programme, is an example of this strategy in action.

The ODIN design will utilise conventional sintered pellet uranium dioxide (UO2) fuel with up to 20% enrichment, “helping to minimise the required development and testing programme schedule and costs”. The low pressure coolant will “minimise the stress on structural components, improve their reliability and service life”. It will also “use a unique reactivity control system design, aiming to have high reliability and robustness through minimizing the number of moving parts”.

The reactor will operate at higher than conventional water-cooled reactor temperatures, which will allow resilient operation and high-power conversion efficiency in generating electricity. The design aims to take maximum advantage of natural convection of coolant for heat transfer to the power conversion cycle at full power and for decay heat removal during reactor shutdown, operational transients, and off-normal conditions.

NANO Nuclear believes there is significant potential for the ALIP technology to be separately commercialised within a year as a component for liquid metal and molten salt-based nuclear reactors. Most advanced nuclear reactor designs utilise liquid-metals and molten salts for cooling and heat transfer functions in the fission and fusion energy industries. They may also have a role in the advanced materials, space exploration, marine propulsion, and high-temperature and industrial process sectors. Some groups that employ technologies where the ALIP technology could potentially be used include TerraPower, Oklo, Commonwealth Fusion Systems, Tokamak, NASA, DOE, GE-Hitachi and Rolls-Royce Marine.

“Although based on known physical principles, this technology is cutting edge,” said Professor Eugene Shwageraus, Lead of Nuclear Reactor Engineering at NANO Nuclear Energy. “It allows pumping of electrically conducting liquids without moving parts. The technology will offer a major advantage to our ODIN design. Forced circulation of coolant at normal operation will allow a substantial increase in the core power density, while improving reliability and reducing maintenance requirements. The low flow resistance of these pumps also improves the passive decay heat removal capability using natural circulation – another key feature of the ODIN reactor design.”