The United Kingdom Atomic Energy Authority (UKAEA) has awarded contracts to 18 organisations to demonstrate how their innovative technologies and proposed solutions can help to commercialise fusion energy. The contracts are for feasibility studies from £50,000 ($60,000) to £200,000.

The United Kingdom Atomic Energy Authority (UKAEA) has awarded contracts to 18 organisations to demonstrate how their innovative technologies and proposed solutions can help to commercialise fusion energy. The contracts are for feasibility studies from £50,000 ($60,000) to £200,000.

They are funded by the UKAEA’s Fusion Industry Programme (FIP) and awarded through the UK government platform Small Business Research Initiative. FIP, established in 2021, is part of the government’s £484m support package for UK research, announced in 2022. FIP was allocated £42.1m to stimulate innovation and to accelerate the development of the fusion industry. This is the second FIP funding cycle.

The 18 organisations will focus on overcoming specific technical and physical challenges. Their projects aim to tackle particular problems slowing the commercialisation of fusion energy such as the need for novel fusion materials and manufacturing techniques and innovative heating and cooling systems.

Tim Bestwick, UKAEA’s Chief Technology Officer, said the past 12 months have witnessed significant advances both in the UK and globally. “However, there are a number of significant technical challenges to address for fusion energy to realise its potential,” he noted. “The Fusion Industry Programme is helping engage organisations and industrial partners to stimulate innovation and address these important challenges.”

Contracts have been awarded to start-ups, small-medium enterprises, established companies, and academia, with six of the 18 organisations receiving funding through FIP for the first time. They fall into two groups. The first group involves “driving up fusion power plant performance with innovative heating and cooling systems”. Organisations in this category include:

- CAL GAVIN Ltd – critical heat flux shifter device

- TWI Ltd – CoreFlow for simplifying fusion reactor thermal management

- IDOM (UK) Ltd – Jet impingement technology transfer

- University of Manchester – development of tungsten diamond composites for nuclear fusion applications.

The second group involves “Improving fusion power plant availability with novel fusion materials, technology, and manufacture”. Organisations include:

- University of Birmingham – FATHOM (Fabrication of Tungsten using hot isostatic pressing and additive manufacturing)

- Full Matrix Ltd – In-situ health monitoring of nuclear fusion supply pipes

- Alloyed Ltd – AMRSAF (additively manufactured RAFM steels for applications in fusion)

- QDOT Technology Ltd – AM+ COOL (Indirect additive manufacture for complex high-performance, cooling devices)

- Astral Neutronics Ltd – tritium breeding materials testing capability with a novel compact fusion neutron source

- Laser Additive Solutions Ltd – AM4F (additive manufacturing for non-coolant components of fusion reactors)

- Archer Technicoat Ltd – BROCCOLi (barrier-layers of rare-earth oxide coatings to corrosion in liquid-lithium)

- Oxford Sigma – liquid lithium corrosion resistant materials for breeder blankets

- 3-SCI Ltd – ultra high temperature electrical distributed sensing

- Fraser-Nash Consultancy Ltd – plasma drift-orbit separation for Li enrichment

- Castings Technology International Ltd – TITAN (opTimised castIng of reduced activation Alloys for fusioN)

- Duality Quantum Photonics Ltd – TRONN: tokamak-robust optical neural networks

- Swansea University – RADIANT (Rapid Alloy Development for Nuclear Technologies)

- TWI Ltd – cold spray additive of oxide dispersion strengthened alloys

- Jacobs UK Ltd – liquid lithium testing facility

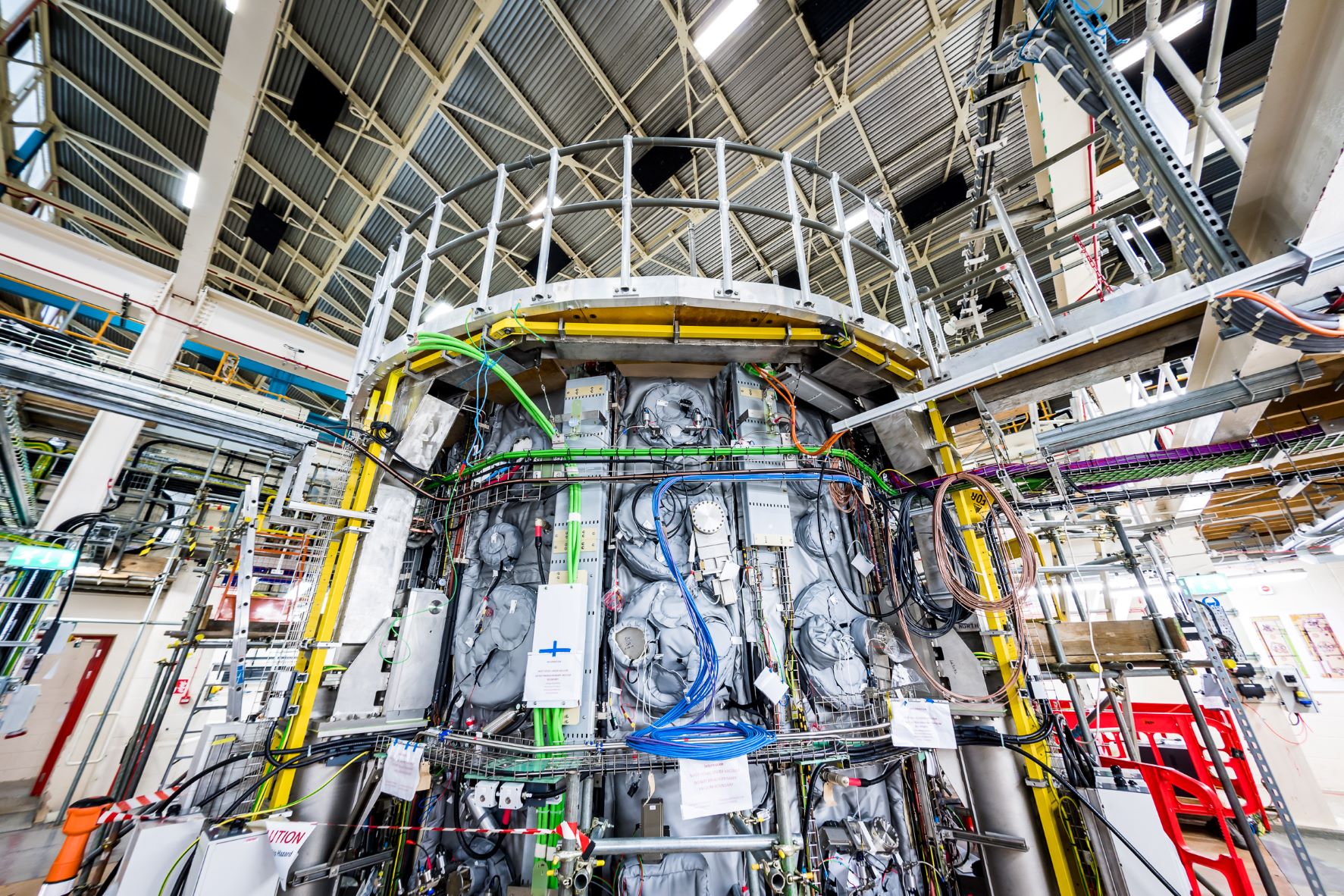

Image: A fusion energy machine at UKAEA's Culham campus (courtesy of SMD Photography)