France’s Orano group has launched its first manufacturing plant in Cherbourg for the assembly of its next-generation TN Eagle casks. The opening ceremony was attended by Claude Imauven, Chairman of the Orano Board of Directors, and Frédéric de Agostini, Senior Executive Vice President in charge of Nuclear Packaging & Services, together with customers, elected officials and economic stakeholders from the region.

The TN Eagle is Orano’s latest generation packaging model, for the transport and dry storage of used NPP fuel. The packaging was approved in 2020 by the French Nuclear Safety Authority (Autorité de Sûreté Nucléaire – ASN) in accordance with the latest regulations from the International Atomic Energy Agency (IAEA). It was granted transport approval from the US Nuclear Regulatory Commission in November 2023 after undergoing rigorous testing to demonstrate its robustness and resistance to extreme transport conditions. For the US, the format for storing used fuel in canisters required adapting TN Eagle’s design.

The production of the TN Eagle is based on innovative manufacturing processes. The packaging is assembled in half the time of equivalent models on the market through the use of fully automated manufacturing lines and without welding. Several models of the TN Eagle have been manufactured, confirming the technical feasibility of the processes.

Orano launched the construction of the new TN Eagle 4.0 manufacturing factory in February 2023 with the support of the France Relance investment fund. This new production unit, located at the port of Cherbourg, was needed to better manage the growing number of orders for the TN Eagle in Europe, Asia and the US.

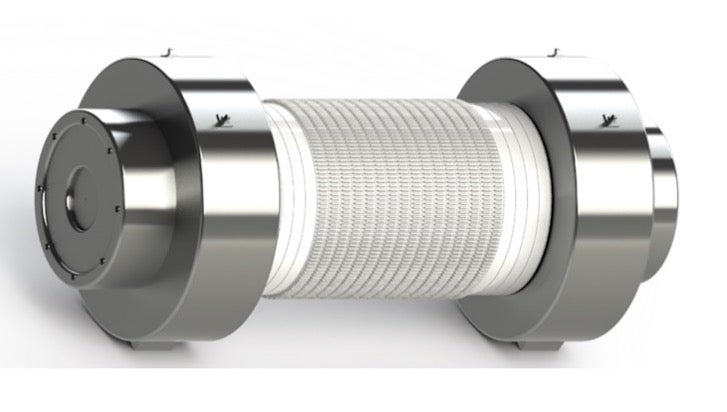

Featuring an innovative design and modular structure, the cask is 5 metres long, 3 metres in diameter and weighs 150 tonnes, allowing Orano to meet the needs of power plant operators while improving safety and competitiveness. Orano has already received numerous orders for several dozen of TN Eagle casks from French and international customers.

The fully automated TN Eagle Factory, equipped with manufacturing processes featuring disruptive technology, can assemble weld-free packages in 15 months, compared with an average of more than 40 months for previous generation products. With a surface area of 6,600 m², the TN Eagle Factory has a production capacity of up to 30 packages a year. Orano entrusted construction of the building to Normandy developer SHEMA, and the assembly line to the companies Latesys and Metrasur.

Implementation of these new processes has been made possible thanks to a design that is innovative in itself. With up to ten times fewer parts than similar packaging, zero welding and exceptional modularity, the TN Eagle design optimises manufacturing while benefiting from greater robustness.

Orano CEO Nicolas Maes said: “This project reflects the group’s desire to develop innovative solutions, combining Orano’s historical expertise in the field of nuclear packaging and cutting-edge technologies. This new industrial facility located in the area of Nord-Cotentin, allows us to maximise our support for the needs of our customers all over the world.”