The United Kingdom Atomic Energy Authority (UKAEA) and the Oxford Robotics Institute (ORI) at the University of Oxford have completed the first ever trial deployment of an autonomous robot at a fusion facility.

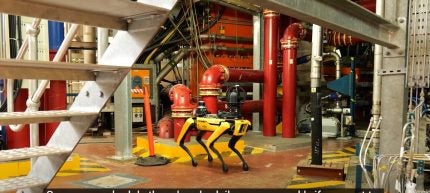

The 35-day trial at UKAEA’s Joint European Torus (JET) facility provided an ideal opportunity to test ORI’s autonomy platform AutoInspect controlling a Boston Dynamics Spot quadruped robot in an environment still hazardous after two high-powered deuterium-tritium experiments in the past three years.

JET in Culham near Oxford. one of the largest and most powerful fusion research machines in the world, was closed at the end of December 2023 after 40 years of operation and is now preparing for decommissioning.

In February, the Remote Handling Control Room at the UKAEA underwent a significant upgrade providing one of the most advanced robotics and remote handling systems in the world for JET. UKAEA said this will support its role in delivering the highest standards in fusion repurposing and decommissioning projects.

A world-leading robotics alliance has now successfully demonstrated that part of a fusion facility’s maintenance can be carried out by an autonomous robot, making such work safer for humans and more cost efficient for its operator. Fusion powerplants will need regular maintenance. Traditionally, robotic inspections required humans to make decisions and to control operation.

“The project aimed to validate the reliability of autonomous robotic technology and instil trust and confidence in their use for safe and efficient inspections in fusion facilities over extended periods,” said Dr Robert Skilton, Head of Research, at UKAEA’s Remote Applications in Challenging Environments division.

Such advancements pave the way for autonomous maintenance and decommissioning in future fusion facilities where human access may be limited owing to challenging conditions posed by radiation, vacuum-level pressure and extreme temperatures.

“This deployment demonstrates that autonomous robots can enhance safety and cut costs. These ‘next generation’ solutions are becoming ready to be used in other industrial facilities such as nuclear decommissioning, environmental clean-up, and disaster relief,” Dr Skilton noted.

The inspection tasks at JET involved mapping the entire facility, taking sensor readings of its environment, and avoiding obstacles and personnel involved in the decommissioning process. This integrated robotic system collected essential data on JET’s environment and overall status twice a day. This allowed the team to assess the feasibility of replacing human inspections with fully autonomous processes.

To address these challenges, UKAEA’s inspection payload was integrated with ORI’s localisation and mission autonomy solutions, developed through a collaboration between the teams of Nick Hawes, Professor of AI & Robotics at the University of Oxford and Maurice Fallon, Associate Professor of Robotics at University of Oxford. This setup was combined with Boston Dynamics’ hardware and collision avoidance technology to enhance the robot’s capabilities.

Professor Hawes described ORI’s aims in the project. “Projects like this demonstrate the value of autonomous robots – robots that can do things themselves without direct control of humans. They also ground our science in real use cases, and provide requirements and constraints that drive us to invent new AI and robotics algorithms.”

ORI’s work in this project was supported by the Engineering and Physical Sciences Research Council through the Embodied Intelligence: From Sensing to Collaboration programme grant which aims to create autonomous systems that enhance human capability and potential. The results will assist planning for the next stages of the JET decommissioning and repurposing programme.

Researched and written by Judith Perera