Rosatom scientists have successfully completed the first stage of reactor testing of laboratory fuel samples for a high-temperature gas-cooled reactor (HTGR) under extremely high temperature conditions. Development of HTGRs are seen as key to developing technology for the production of low-carbon hydrogen and ammonia using HTGR heat. Rosatom is also developing HTGR fuel and pilot industrial technology as part of an investment project to create domestic technologies for large-scale production and consumption of hydrogen and hydrogen-containing products.

Reactor tests of laboratory samples of HTGR fuel at a temperature that can be reached in the event of a violation of the normal operating conditions of the HTGR reactor have been carried out since 2024 in the SM-3 reactor at the Scientific Research Institute of Atomic Reactors (NIIAR – Nauchno Issledovatelskii Institut Atomnikh Reaktorov) in Dimitrovgrad. The programme for reactor testing of HTGR fuel under extreme and emergency operating conditions was prepared by Dimitrovgrad scientists together with specialists from JSC Research Institute NPO LUCH (designer-technologist and manufacturer of fuel elements), JSC OKBM Afrikantov (chief designer of the reactor plant) and National Research Centre Kurchatov Institute (scientific director of the project).

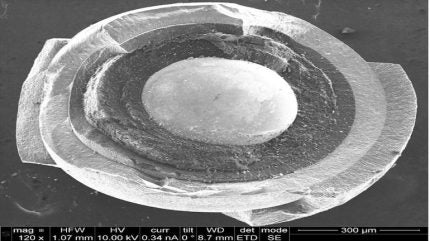

At the first stage of research, HTGR fuel samples previously tested in the SM-3 reactor (for more than 400 effective days at a temperature in the range of 1000-1200°C) were irradiated for more than 700 hours at a maximum temperature of 1600°C. This is a temperature which could occur in the event of a violation of normal operating conditions of the HTGR reactor. Based on the test results, it was confirmed that the multilayer protective coating of the spherical fuel core of HTGR fuel TRISO (TRI-structural ISOtropic) particle fuel, reliably retains the gaseous products formed during the fission of nuclear fuel, even under conditions of prolonged irradiation at temperatures of approximately 500°C above the parameters of normal operation of the reactor.

Such reactor experiments under extreme and emergency operating conditions are an integral element of the development, determination of operational limits and licensing of nuclear fuel. It was previously reported that, by the end of 2023, at the experimental site of the Rosatom Scientific Division, reactor tests of laboratory samples of HTGR fuel were successfully completed at a temperature of 1000-1200°C, achieving burn-up corresponding to the design values for the operation of HTGR fuel.

“Reactor tests at temperatures of 1600°C, carried out by NIIAR specialists in 2024 as part of the comprehensive programme of computational and experimental testing of HTGR fuel we are implementing, complement the previously obtained results of irradiating HTGR fuel samples to design burn-up values,” noted Andrey Mokrushin, head of the work to develop HTGR fuel and Deputy General Director for Science of JSC Research Institute NPO LUCH. “They confirm the performance of the developed fuel design in case of disruption of normal operation and allow us to form a reasonable understanding of the design limits of HTGR fuel operation in order to ensure the safe operation of the HTGR reactor.”

In 2025, Rosatom specialists plan to implement the second stage of the programme for reactor testing of HTGR fuel under extreme and emergency operating conditions, within the framework of which HTGR fuel samples pre-irradiated to various burn-ups will be tested for a long time at temperatures of up to 1800°C.