Russia’s Mining & Chemical Combine (MCC part of Rosatom”, Environmental Solutions division) in Zheleznogorsk has started testing the steel which is planned for the manufacture of equipment for the future molten salt research reactor (IZhSR – Issledovatelskovo Zhidko Solevovo Reaktora).

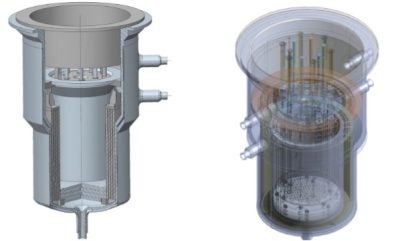

During the tests, several tasks will be performed: to confirm the possibility of using the selected steel samples in the project; to track changes in the impurity composition of salt as a result of corrosion of samples; and to test a method for cleaning fuel salt. The steel samples will spend 4,000 hours in an aggressive environment – in molten salts heated to almost 700℃ and containing radiotoxic minor actinides.

The programme and R&D methods were developed by MCC together with the Ural Federal University, which also supplied some of the equipment. The documents were approved by the NA Dollezhal Scientific Research & Design Institute of Power Engineering (Nikiet) – the main design organisation of work on the construction of IZhSR.

“Everything that will be created around IZhSR is new. Therefore, MCC, as the operating organisation, should study all the possibilities … from the preparation of fuel salt to the selection of structural materials. But the most important thing is to compare all the results with the goals and objectives set,” said Vladimir Matselya, Director of the Scientific and Production International Centre for Engineering Competencies at the State Medical & Industrial Institute.

“Energy without radioactive waste is the dream of nuclear scientists around the world and Russia is the furthest along in making this dream a reality,” said Vasily Tinin, Director of State Policy on Radwaste, Used Fuel and Decommissioning of Radiation Hazardous Facilities at Rosatom. The research reactor, which is planned for construction at MCC in Zheleznogorsk, is an important project from an environmental point of view. It will serve to test technologies for the utilisation of minor actinides. These are the long-lived, highly radiotoxic isotopes that remain after the reprocessing of used fuel from currently operating thermal reactors.”

After completion of the tests, the steel samples will be removed, decontaminated and the necessary measurements will be carried out to determine mechanical and corrosion properties (in accordance with available methods). Based on the results, a conclusion will be made on whether the steel is suitable for the manufacture of auxiliary equipment.

Work on the molten salt research reactor at MCC is carried out within the framework of the state programme, Development of Engineering, Technologies & Scientific Research (RTTN – Razvitii Tekhniki Tekhnologii I Nauchnikh Issledovanii) in cooperation with enterprises and organisations in the industry. The physical launch of IZhSR is planned for 2030.