Researchers at Russia’s AN Frumkin Institute of Physical Chemistry & Electrochemistry of the Russian Academy of Sciences (IPCE-RAS) and the National Research Nuclear University (NRNU) MEPhI [Moscow Engineering & Physics Institute] have developed a technology to protect the walls of fusion reactors.

Researchers at Russia’s AN Frumkin Institute of Physical Chemistry & Electrochemistry of the Russian Academy of Sciences (IPCE-RAS) and the National Research Nuclear University (NRNU) MEPhI [Moscow Engineering & Physics Institute] have developed a technology to protect the walls of fusion reactors.

In tokamaks, plasma is held in place by a magnetic field, but plasma flows can still come into contact with the reactor wall causing damage. The heated wall material is therefore sprayed with a protective coating but this can enter the plasma as an impurity. As a result, the plasma cools, which can interfere with nuclear fusion.

The “sweat wall” concept involves covering the inside of the reactor with a network of channels from which liquid lithium flows. The nuclei of such a light element hardly cools the plasma. The material for the “sweating” wall must be refractory and thermally conductive and must not enter into chemical interaction with liquid lithium.

“The choice of material for plasma-facing elements is still a matter of scientific debate. Testing of various materials and methods of their conjugation, as well as protective coatings, is now being carried out,” said Vladimir Dushik, head of the laboratory of heterogeneous synthesis of refractory compounds at IPCE-RAS.

Scientists from the two Russian institutes therefore proposed using a chemical vapour deposition method to combine the properties of two metals, tungsten and copper.

“Tungsten, with its record high melting and boiling points, can withstand high thermal loads and does not interact with liquid lithium,” explained Dushik.”In the form of a coating on copper, tungsten shows higher efficiency due to the significantly higher thermal conductivity of copper. The solution is to deposit a 30 µm tungsten layer on a copper substrate. This layer will take the main attack – of both plasma and chemically active lithium.”

According to Dushik, coatings obtained from the gas phase have low porosity, which prevents interaction of the copper substrate with liquid lithium. They also have high purity, which prevents contamination of the tokamak working space.

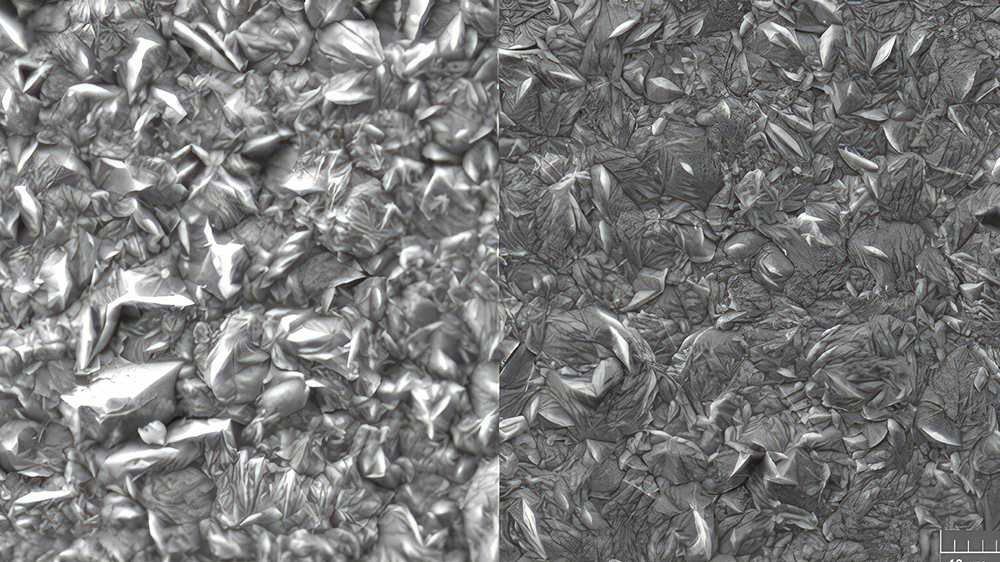

“A pilot batch of coatings on model copper substrates has undergone a series of tests at the NRNU MEPhI and the Research Institute of Electrophysical Equipment,” noted Dushik. “Tests on lithium wettability and lithium flow in a vacuum, heat dissipation uniformity and thermal cycling have shown that, despite the difference in the thermal expansion coefficients of tungsten and copper, as well as the low thickness, the tungsten coating retains its durability, integrity and protective properties.”

Image courtesy of Rosatom