Pilot operation has begun at the innovative fuel fabrication/refabrication plant (MFR-YaT – Modulya po Fabrikatsii/ Refabrikatsii Yadernovo Tolpliva) in Seversk, Tomsk Region. The fuel plant intended to support the Brest-OD-300 lead-cooled fast reactor is part of the IV generation Experimental Demonstration Energy Complex (ODEK – Opitno Demonstratsionovo Energo-Kompleksa), which is being developed at the Siberian Chemical Combine (SCC) in Seversk under the Breakthrough (Proryv) project intended to demonstrate closed fuel cycle technology.

In addition to the nuclear power plant with the BREST-OD-300 reactor, ODEK will also include on-site nuclear fuel cycle facilities – a complex for the production of mixed uranium-plutonium nitride fuel, as well as a module for reprocessing irradiated nuclear fuel. At the moment, at the construction site of the BREST-OD-300 power unit, the installation of a cooling tower has been completed, the walls of the reactor building have been erected to an elevation of +16.850 meters, the reactor shaft has been erected, and the enclosing structure of the reactor vessel has been installed.

The MFR is the first of three facilities planned at ODEK to begin operation. Brest (Bistrii Reaktor Estestvennoi-bezopasnosti co Svinstovim Teplonositelem – Fast Natural-safety Reactor with Lead Coolant) is a Generation IV 300 MWe power unit nearing completion and scheduled to begin operation in 2027. The third facility will be a module for reprocessing irradiated fuel from Brest. Construction of the reprocessing unit is planned for 2025-2026 for commissioning in 2030.

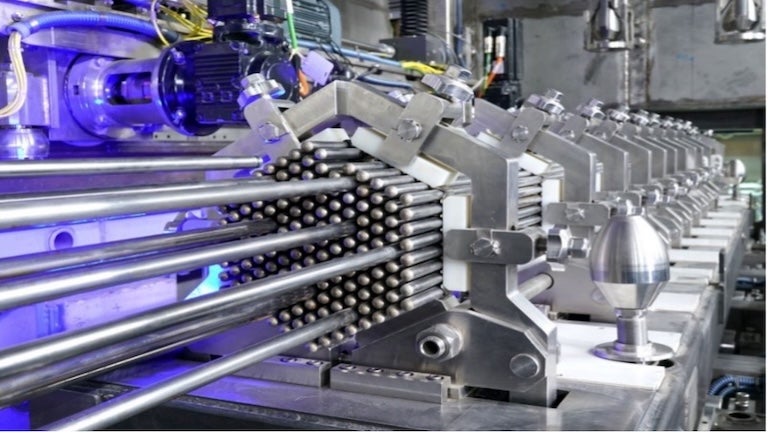

The ultra-modern and fully automated MFR production facility has already successfully produced the first prototype fuel cassettes for the Brest core based on mixed dense nitride uranium-plutonium fuel (SNUP). SNUP fuel is based on two key components – depleted uranium, which is a by-product of uranium enrichment for nuclear reactors, as well as plutonium extracted from irradiated nuclear fuel.

All production areas of the new plant have undergone comprehensive testing. In total, four technological lines were created at the MFR: carbothermal synthesis of mixed uranium and plutonium nitrides, production of fuel pellets, production of fuel elements, and assembly of complete fuel cassettes. The core number of technological personnel at the facility will be 250 people.

Currently, the production facility is testing the technology for the fabrication of Brest fuel assemblies with a fuel composition based on depleted uranium in accordance with the licence issued by regulator Rostechnadzor on 29 March. After the regulator approves the handling of plutonium, the scientists will be able to begin production of SNUP fuel. To start loading the reactor, more than 200 fuel assemblies with SNUP fuel will have to be manufactured.

A unique technology for the fabrication of nitride uranium-plutonium fuel was developed by Rosatom scientists. Fuel assemblies with experimental fuel rods based on SNUP fuel were successfully tested in the BOR-60 research reactor at the Dimitrovgrad Research Institute of Nuclear Reactors (NIIAR – Nauchno Issledovatelskii Institut Atomnikh Reaktorov), as well as in the commercial BN-600 fast reactor at unit 3 of the Beloyarsk NPP. As a result, the data necessary to justify the starting load of the Brest reactor was obtained, including the level of nuclear fuel burn-up required at this stage.

Once the three ODEK facilities are in operation they will comprise the world’s first nuclear power plant with a fast reactor and an on-site closed nuclear fuel cycle. Irradiated fuel after reprocessing will be sent for refabrication (the re-production of fresh fuel). Thus, this system will become practically autonomous and independent of external energy supplies.

“Today, Rosatom is leading the world in the development of Generation IV nuclear technologies,” said Rosatom Director General Alexey Likhachev. “According to the IAEA classification, this implies higher efficiency in the use of uranium fuel raw materials, increased safety standards for the operation of nuclear installations, as well as a significant reduction in the volume of nuclear waste generation. All these principles are fully consistent with the technological solutions adopted at ODEK both for fuel from depleted uranium and plutonium, and for the Brest reactor facility, based on the principles of natural safety, and for the latest, more efficient radiochemistry technologies for processing irradiated fuel.”

To ensure the fabrication of fuel at the MFR, new production facilities were created at the enterprises of Rosatom’s Fuel Division TVEL. In particular, the production of various components for the initial fuel load, as well as the Brest simulation zone, was mastered at the Chepetsk Mechanical Plant in Glazov (ChMZ – Chepetskom Mekhanicheskom Zavode)), the Mechanical Engineering Plant in Elektrostal (MSZ – MashinoStroitelnom Zavode)) and at the Novosibirsk Chemical Concentrates Plant (NZKhK -Novosibirskom Zavode KhimKontsentratov).

Brest-OD-300 will be the world’s first reactor plant with a lead coolant; its architecture is based on the principles of natural safety. The efficiency of the reactor will also be ensured through the use of the SNUP fuel comprising entirely secondary products of the nuclear fuel cycle – depleted uranium and plutonium. Its use will make it possible to significantly expand the resource base of nuclear energy, to reprocess irradiated fuel assemblies to produce fresh fuel instead of storing it, and also to radically reduce the volume of nuclear waste and its activity.

Thermal neutron reactors, which form the basis of modern nuclear energy, use about 1% of uranium, the remaining 99% is sent for temporary storage or disposed of as radioactive waste. The advantage of fast neutron reactors is the ability to efficiently use secondary products of the fuel cycle (in particular, plutonium) for energy production. At the same time, having a high reproduction factor, fast reactors can produce more potential fuel than they consume, as well as afterburn highly active transuranium elements (actinides).

Generation IV nuclear energy systems are capable of radically changing nuclear energy, primarily due to a new level of safety, expansion of the fuel range and a significant reduction in radioactive waste. Russia is one of the leaders in the development of these technologies. As well as ODEK, at the Beloyarsk NPP, pre-design work has begun on the construction of the BN-1200M power unit – the world’s largest fast reactor (Beloyarsk 5).

By the end of 2025, the design documentation for the main stage of the construction of the power unit will be transferred for approval to the Beloyarsk NPP. In 2026, it is planned to conduct a state examination of project documentation and send an application to regulator Rostekhnadzor for a construction licence. Rosenergoatom is making every effort to start the main work in a timely manner, as the first concrete is scheduled for June 2027.

The service life of the BN-1200M power unit will be at least 60 years. The project uses technical solutions that have proven themselves during the operation of predecessor fast reactor power units – the BN-600 (Beloyarsk unit 3) and the BN-800 (Beloyarsk 4). Justification of structural materials and fuel for the BN-1200M is based on the operation of the BN-600.

Meanwhile, 17 employees from ODEK have completed an internship at the Beloyarsk NPP, where they studied the operational technical documentation and the organisation of operation of the power units. The internship was part of the advanced training of ODEK personnel and included individual programmes for a wide range of production areas as well as a technical tour including the control, turbogenerator and central hall of the BN-800.

For our employees, this internship is very important,” said Ivan Babich, director of the Brest power unit. “It is important for staff to see all the nuances of fast reactor operation. In addition, the internship helps to build business and informal relationships between nuclear scientists, making it possible to effectively interact on any production issues.”