US TerraPower executives, including Chairman Bill Gates took part in the groundbreaking ceremony of the company’s planned Natrium reactor facility in Kemmerer, Wyoming. Also attending the ceremony were TerraPower CEO Chris Levesque, and government representatives as well as South Korean officials including SK Group Vice Chairman Yoo Jung-joon and SK Executive Vice President Kim Moo-hwan.

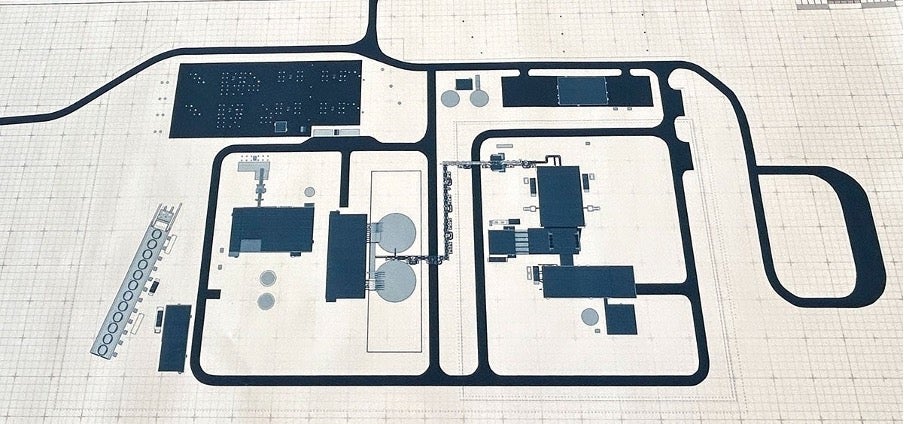

In November 2021, TerraPower selected an ageing coal plant in Kemmerer owned by US PacifiCorp as the preferred site for the demonstration project. The site is adjacent to PacifiCorp’s Naughton Power Plant, which will stop burning coal in 2026 and natural gas a decade later, according to the utility. Natrium is a TerraPower and GE-Hitachi technology and is one of two competitively-selected Advanced Reactor Demonstration Program (ARDP) projects supported by the US Department of Energy (DOE).

The construction project is expected to cost up to $4bn, half funded by the ARDP. The company has raised about $1bn, including investments from Gates as well as South Korea-based SK Inc and SK Innovation, according to PitchBook. DOE has provided long-standing support for TerraPower’s Molten Chloride Fast Reactor (MCFR) project. In 2016, DOE awarded a five-year, $40m cost-share award for continued R&D. This resulted in a new public-private MCFR project development partnership including TerraPower, Southern Company, Oak Ridge National Laboratory, the Electric Power Research Institute, and Vanderbilt University. DOE awarded TerraPower $80m in initial funding to demonstrate its Natrium technology.

According to the TerraPower website, the ARDP authorises a 50/50 cost share and authorises up to $2bn for the Natrium project. “TerraPower and partners will match this investment dollar for dollar. The first-of-a-kind cost for the Natrium demonstration plant will include the reactor design and licensing, codes and methods development, fuel development and qualification, and the design, construction and operation of two supporting facilities: the Natrium Fuel Fabrication Facility and Sodium Test and Fill Facility. The sodium facility will be used to test and demonstrate the performance of first-of-a-kind equipment prior to operations in the reactor plant.”

The Natrium technology is a TerraPower and GE-Hitachi technology featuring a 345 MWe sodium-cooled fast reactor with a molten salt-based energy storage system. The storage technology is intended to boost the system’s output to 500 MWe for more than five and a half hours when needed to integrate with variable renewable energy sources. Along with PacifiCorp and GE Hitachi Nuclear Energy, members of the demonstration project team include engineering and construction partner Bechtel, Energy Northwest, Duke Energy and nearly a dozen additional companies, universities and national laboratory partners.

The US Nuclear Regulatory Commission (NRC) in May accepted TerraPower’s construction permit application for review, marking the first time in more than 40 years that the NRC has docketed this type of application for a commercial non-light water reactor. TerraPower’s current work is to have the site ready to build the reactor as soon as the company receives a the final construction permit from NRC.

Southern Company and TerraPower are working on an Integrated Effects Test (IET) to learn how the MCFR technology will scale and behave at larger, commercially relevant sizes. The IET was commissioned and began operating in TerraPower’s Everett, Washington, facility in October 2023.

TerraPower’s demonstration plant, planned for Kemmerer, is intended to validate the design, construction, and operational features of the Natrium technology. However, in December 2022, TerraPower postponed the expected start date of the reactor by at least of two years. The company had originally hoped to commission the plant in 2028 using Russian-supplied high-assay low-enriched uranium (HALEU) fuel to get the demonstration unit up and running by 2028. The conflict in Ukraine, however, has made continuing Russian HALEU deliveries unlikely and the US has yet to develop its own supplies. The projected commissioning date is now 2030.

Bill Gates, discussing the ground-breaking ceremony on his GatesNotes personal blog, claims: “Kemmerer, Wyoming will soon be home to the most advanced nuclear facility in the world.”

He says: “The plant was designed by TerraPower, a company I started in 2008. But my nuclear journey started several years earlier, when I first read a scientific paper for a new type of nuclear power plant. The design was far safer than any existing plant, with the temperatures held under control by with the laws of physics instead of human operators who can make mistakes. It would have a shorter construction timeline and be cheaper to operate. And it would be reliable, providing dependable power throughout the day and night. As I looked at the plans for this new reactor, I saw how rethinking nuclear power could overcome the barriers that had hindered it— and revolutionize how we generate power in the US and around the world…. But that technology was just an idea in a lab and on a computer screen until today.”

Gates expects the NRC review process to take a couple of years. “So in the meantime, TerraPower will continue to build the non-nuclear parts of the facility”. Construction will begin next year on the so-called “energy island,” which is where the steam turbines and other machinery that actually generate power will sit. (The reactor will eventually be part of a “nuclear island,” and the team hopes to start building that in 2026.)” He adds: “While these first-of-a-kind projects can be big and risky, they are too important for our future to fail to act.”

In an earlier blog in May 2023, Gates provides some more comments on the reactor technology. “Like other power plant designs, it uses heat to turn water into steam, which moves a turbine, which generates electricity. And like other nuclear facilities, it generates the heat by splitting uranium atoms in a chain reaction. But that’s pretty much where the similarities stop.”

He continues: “A typical reactor keeps the atom-splitting nuclear reaction under control by circulating water around a uranium core. But using water as a coolant presents two challenges. First, water isn’t very good at absorbing heat — it turns to steam and stops absorbing heat at just 100 degrees C. Second, as water gets hot, its pressure goes up, which puts strain on your pipes and other equipment. If there’s an emergency — say, an earthquake cuts off all the electricity to the plant and you can’t keep pumping water — the core continues to make heat, raising the pressure and potentially causing an explosion.”

He therefore believes liquid metal is a better coolant than water. “The Natrium plant uses liquid sodium, whose boiling point is more than eight times higher than water’s, so it can absorb all the extra heat generated in the nuclear core. Unlike water, the sodium doesn’t need to be pumped, because as it gets hot, it rises, and as it rises, it cools off. Even if the plant loses power, the sodium just keeps absorbing heat without getting to a dangerous temperature that would cause a meltdown.”

On the plant’s molten salt energy storage system, he says this will allow the Natrium facility to control how much electricity it produces at any given time. “That’s unique among nuclear reactors, and it’s essential for integrating with power grids that use variable sources like solar and wind.”

He also extols TerraPower’s digital design process. “Using supercomputers, they’ve digitally tested the Natrium design countless times, simulating every imaginable disaster, and it keeps holding up. TerraPower’s sophisticated work has drawn interest from around the globe, including an agreement to collaborate on nuclear power technology in Japan and investments from the South Korean conglomerate SK and the multinational steel company ArcelorMittal.”

While the TerraPower website provides some details of work done with molten salt, it contains very little information about the reactor technology. According to a video: “In the reactor building, advanced uranium fuel is inserted into an enclosed container and covered with liquid sodium. A chain reaction starts when uranium atoms slit and release neutrons and heat the metal coolant inside the reactor system…. The liquid sodium is heated and then transfers thermal energy to pipes filled with molten salt. This… then travels to a very large storage tank that serves as a thermal battery for the plant…. The molten salt passes near water-filled tubes and boils the water to make super heated steam. This… then helps to turn a turbine, creating electricity…. The molten salt is transferred to a cold tank and eventually back to the nuclear island.”

Basically the Natrium reactor is a sodium-cooled fast reactora. Currently, the only commercially operating liquid metal-cooled fast reactors are in Russia, using sodium as the coolant. Russia is also constructing the world’s first lead-cooled small modular reactor (Brest-OD-300) in Seversk as part of a facility to demonstrate an on-site closed fuel cycle, including novel fuel fabrication. This reactor, based on decades of complex research and development, and supported by the entire Russian nuclear industry, is due to begin operation in 2029 and probably qualifies as the most advanced reactor facility in the world.

While research on fast reactors took place in the 1960s and 1970s in the US and Europe, things began to change in the late 1970s as concerns about scarce uranium resources waned and public opinion became increasingly hostile in the wake of the 1979 Three Mile Island accident in the USA and the Chernobyl disaster in 1986. By the early 1990s the US, the UK and Germany had closed down their programmes. France continued with its Phenix and SuperPhenix projects for a few more years, finally closing SuperPhenix in 1998 and Phenix in 2009, Subsequently, in 2019, France also cancelled the Generation IV ASTRID sodium-cooled fast reactor demonstrator design project. Although interest is now reviving in Europe and the USA both through collaborative projects and government support for private company initiatives, it remains at the early design phase and is probably decades away from implementation.

As an example, India’s prototype sodium-cooled fast breeder reactor began fuel loading in March. The Indira Gandhi Centre for Atomic Research (IGCAR) began to design the reactor in 1980 and construction began in 2004, 24 years later. It was originally expected to be commissioned in 2010 but suffered a series of delays over the next 14 years.