US-based TerraPower has selected five suppliers to support its Natrium Reactor Demonstration Project in Kemmerer, Wyoming. TerraPower these award selections are integral to the development of the Natrium plant. “Upon completion, the Natrium plant will be a full commercial operating plant and will bring to market clean, reliable, stable baseload energy and flexible energy storage, as well as long-term jobs to energy producing communities.”

Tara Neider, Senior Vice President and Project Director for the Natrium Reactor Demonstration Project said the expertise of these suppliers and the equipment they produce are key to supporting the Natrium technology. “We will continue to put strong emphasis on engaging the diversity of the nuclear supply chain as we bring the Natrium Reactor and Energy Storage System to market.”

The Natrium technology is a TerraPower and GE-Hitachi technology featuring a 345 MWe sodium-cooled fast reactor with a molten salt-based energy storage system. The storage technology can boost the system’s output to 500 MWe for more than five and a half hours when needed to integrate with variable renewable energy sources. Along with PacifiCorp and GE Hitachi Nuclear Energy, members of the demonstration project team include engineering and construction partner Bechtel, Energy Northwest, Duke Energy and nearly a dozen additional companies, universities and national laboratory partners.

In October 2020, the US Department of Energy (DOE), through its Advanced Reactor Demonstration Programme (ARDP), awarded TerraPower $80m in initial funding to demonstrate the Natrium technology.

US PacifiCorp, owner of the ageing Wyoming coal plant selected in 2021 as the future site for TerraPower’s Natrium reactor demonstration project released its 2023 Integrated Resource Plan (IRP) in May 2023. This considers the possible addition of two more Natrium units to the company’s generation resource mix by 2033, under certain circumstances. These could be sited in Utah near currently operating coal-fired facilities.

TerraPower’s demonstration plant, planned for Kemmerer in Wyoming is intended to validate the design, construction, and operational features of the Natrium technology when necessary. However, in December 2022, TerraPower postponed the expected start date of its Kemmerer reactor by at least of two years.

The company had originally hoped to commission the plant in 2028 using Russian-supplied high-assay low-enriched uranium (HALEU) fuel to get the demonstration unit up and running by 2028. The conflict in Ukraine, however, has made continuing Russian HALEU deliveries unlikely and the US has yet to develop its own supplies. The projected commissioning date is now 2030. Volume 2 of the IRP comprises more than 400 pages of appendices. The Appendix on regulatory compliance includes the following comment: “Finally, we acknowledge the inherent complexities with the Natrium project and direct the Company to continue to assess the risks of technology viability and potential delays with Natrium and plan accordingly.”

TerraPower remains confident, however, that the US supply chain will be ready to support up to five more reactors of the same design in Wyoming and Utah by 2035. Its joint study with PacifiCorp of the available options, announced in October, is on track to be finished late next year.

The latest awards include:

- GERB Vibration Control Systems will support the Natrium Reactor Demonstration Project by providing design and testing services, and supply seismic isolation equipment for the Natrium reactor support structure.

- Thermal Engineering International (USA) to design and fabricate the Sodium-Salt Heat Exchanger. The exchanger transfers heat from the sodium in the intermediate heat transport system, to the salt in the nuclear island salt heat transport system. These heat exchangers reside in the Reactor Auxiliary Building providing for the essential flow and energy transfer of intermediate sodium and salt.

- Hayward Tyler to provide the design, fabrication, testing and qualification for the Primary and Intermediate Sodium Pumps. The Primary Sodium Pumps provide forced cooling for the reactor core by driving sodium through the Primary Heat Transport (PHT) system. The Intermediate Sodium Pumps transport all anticipated heat loads from the PHT to the nuclear island salt heat transport system.

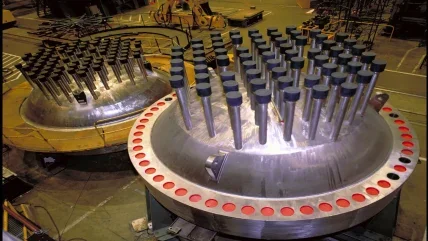

- Framatome US Government Solutions is contracted to design the Ex-Vessel Fuel Handling Machine and Bottom Loading Transfer Cask for the Natrium Reactor Demonstration Project. These machines are an essential part of the fuel handling transport system that supports the nuclear reactor core component handling operations. Successful design of this equipment is vital to meeting the operational goals of the plant.

- Teledyne Brown Engineering to provide the design, fabrication, and testing for the In-Vessel Transfer Machine (IVTM) for the Natrium Reactor Demonstration Project. The IVTM is a digitally controlled, multi-axis, pantograph style fuel handling machine. Its primary function is to manipulate core components from within the reactor vessel during refuelling operations.